Take the risk out of food safety

Streamline and maintain food safety compliance, ensuring you have instant visibility into FSQ data to understand the current status of your operations and potential risks.

Digitize Your

HACCP Planning

See real-time data for live updates, ensuring a comprehensive understanding of your operations, immediate risks, and urgent tasks.

Ensure Regulatory

Compliance

Streamline the auditing of menus, ingredients, and freezer temperatures through automated systems, removing the need for manual methods.

Protect Your Brand &

Your Customers' Health

Real-time reporting to mitigate risks related to recalls or potential hazards, ensuring a more efficient and compliant approach to food service quality.

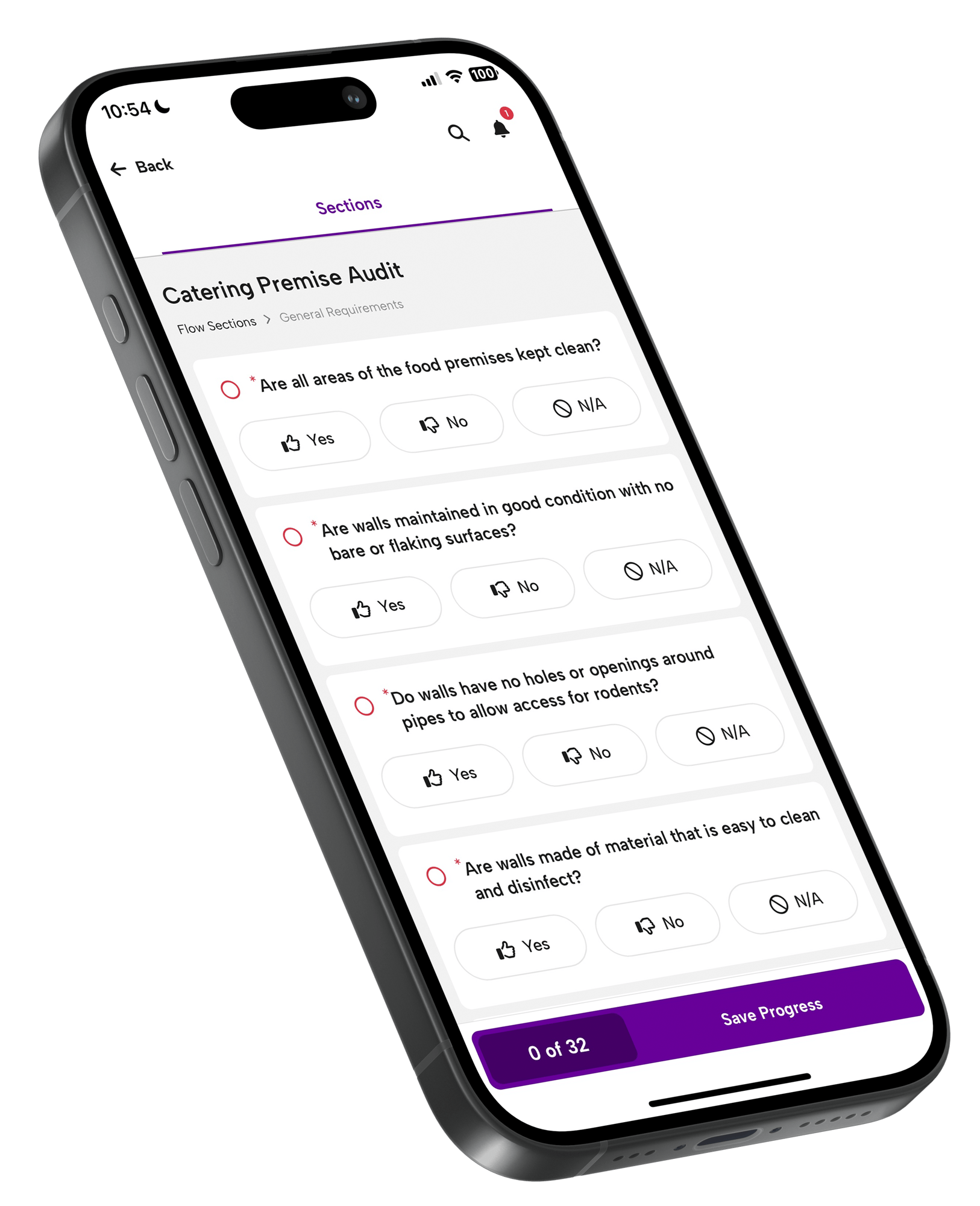

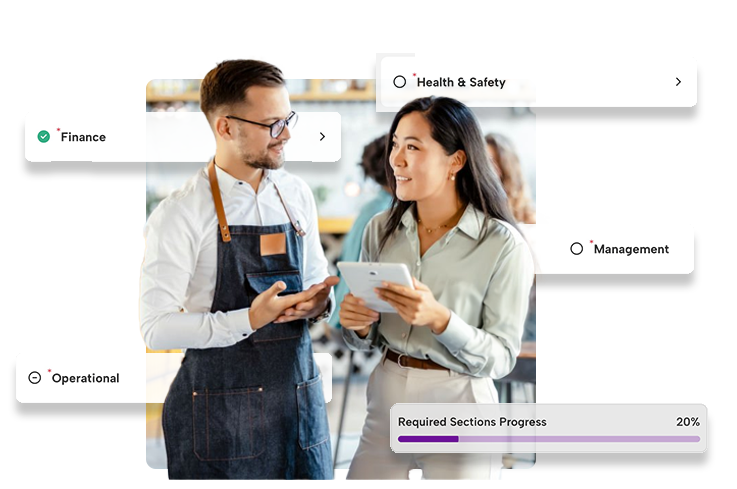

Ensure Compliance Effortlessly with Streamlined Management

Quickly audit for FSQ to avoid regulatory violations and penalties. Track requirements and maintain ongoing compliance documentation.

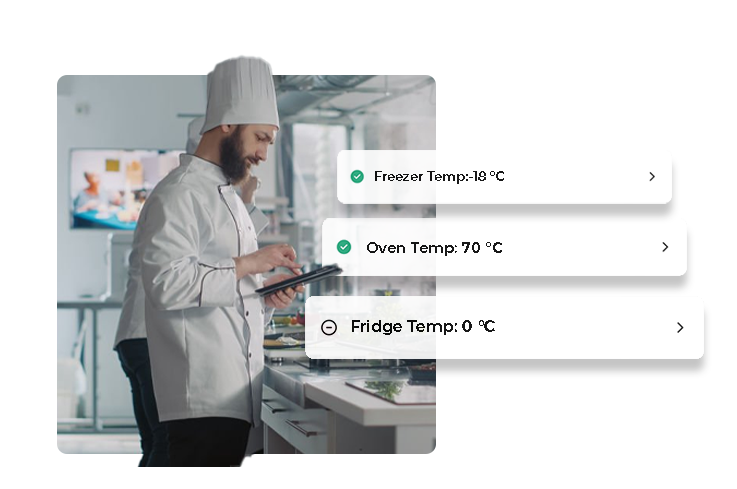

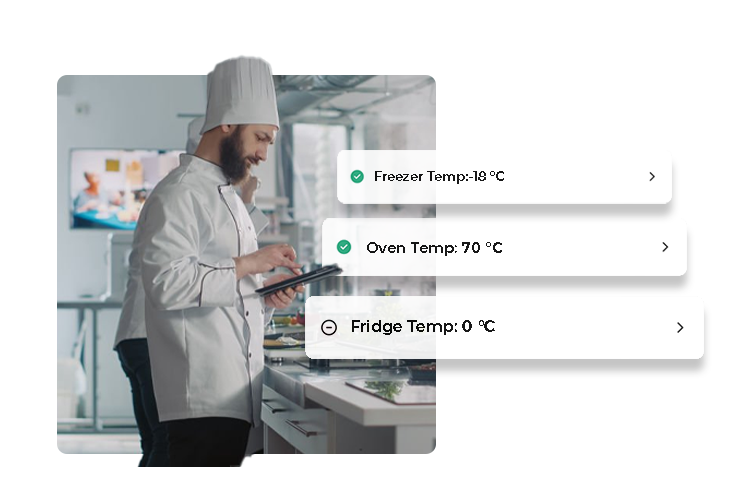

Maintain Optimal Conditions with Temperature Monitoring and Compliance

Automatically report and log temperatures, trigger alerts for any temperature deviations and maintain compliance reporting, ensuring food products are stored and transported under safe conditions.

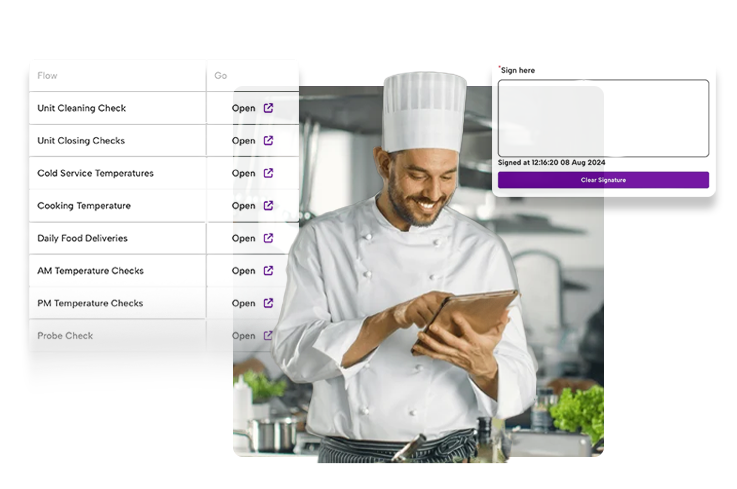

Prevent Hazards with Critical Control Points Management

Monitor for CCPs and document necessary corrective actions to ensure the safety of food products.

Optimize Supplier Relationships with Effective Management

Track supplier compliance in real-time. Conduct necessary audits and digitally manage any documentation for a streamlined and efficient approach that mitigates risk of non-compliant or unsafe materials.

Guarantee Excellence with Quality Control and Assurance

Ensure that products meet quality standards and specifications at all times. Capture quality data in real-time, conduct inspections and tests, and implement corrective and preventative actions.

Enhance Safety with Traceability and Recall Management

Quickly identify and contain food safety incidents or recalls with rapid and accurate traceability of ingredients, products, and batches.

Empower Your Team with Comprehensive Training and Documentation Management

Ensure employees are knowledgeable on food safety compliance at all times. Deliver training materials and track employee certifications and training records.

Select an option below:

- Temperature Monitoring

- Compliance

- HACCP

- Supplier Management

- Quality Control

- Recall Management

- Training and Documentation

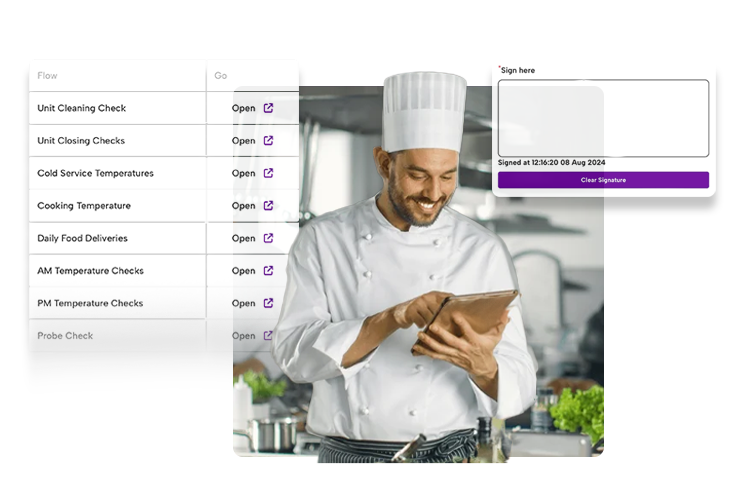

Compliance Management

From recording food temperatures and allergen checklists to monitoring cleanliness levels and preventative maintenance, effective compliance management tools are critical to ensure food safety regulations and standards are maintained at all times. mpro5's food safety compliance software makes it easy to track regulatory requirements, conduct compliance audits and maintain ongoing compliance documentation. With dynamic dashboards that provide real-time reporting, organizations can quickly audit for FSQ to avoid regulatory violations and penalties.

Hazard Analysis and Critical Control Points Management

A Hazard Analysis and Critical Control Points (HACCP) plan is essential for identifying and managing potential food safety hazards. To mitigate risk and ensure effective management, our HACCP compliance software facilitates hazard analysis and establishes critical control points (CCPs). Leveraging real-time data, mpro5’s reporting dashboards monitor for CCPs and document necessary corrective actions to ensure the safety of food products.

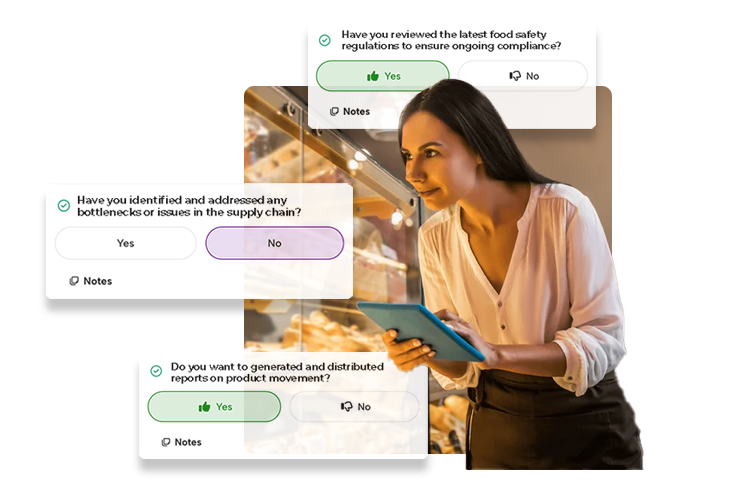

Supplier Management

Supplier and vendor management can be challenging, particularly when something goes wrong, often hurting quality and safety of critical materials and ingredients. Our supplier compliance management software enables food safety and quality professionals to track supplier compliance in real-time, conducting necessary audits and digitally managing any documentation for a streamlined and efficient approach that mitigates risk of non-compliant or unsafe materials.

Quality Control and Assurance

For food safety and quality professionals, maintaining consistent quality control and assistance is essential not only to ensure customer satisfaction and positive brand reputation, but also to mitigate costly risks. At mpro5, we help streamline quality control and assurance processes through our process management software by capturing quality data in real-time, conducting inspections and tests, and implementing corrective and preventative actions. Our automated workflows reduce slow manual management, ensuring that products meet quality standards and specifications at all times.

Traceability and Recall Management

With food recalls a frequent occurrence, mpro5’s food traceability software streamlines the traceability and recall management process in full, ensuring full visibility each step of the way. With rapid and accurate traceability of ingredients, products, and batches, food safety and quality professionals can quickly identify and contain food safety incidents or recalls using our software for food manufacturing. Our dashboards track product movement through the supply chain, enabling efficient recall management and minimizing the impact of food safety incidents on consumers and the brand.

Temperature Monitoring and Compliance

The inability to accurately monitor temperature and maintain compliance with food temperatures can be costly for organizations, as missed temperature changes can result in lost product, delays in production and distribution, as well as creation of foodborne illnesses. mpro5 provides real-time temperature monitoring capabilities through our food safety temperature monitoring systems that automatically report and log temperatures, trigger alerts for any temperature deviations and maintain compliance reporting, ensuring food products are stored and transported under safe conditions.

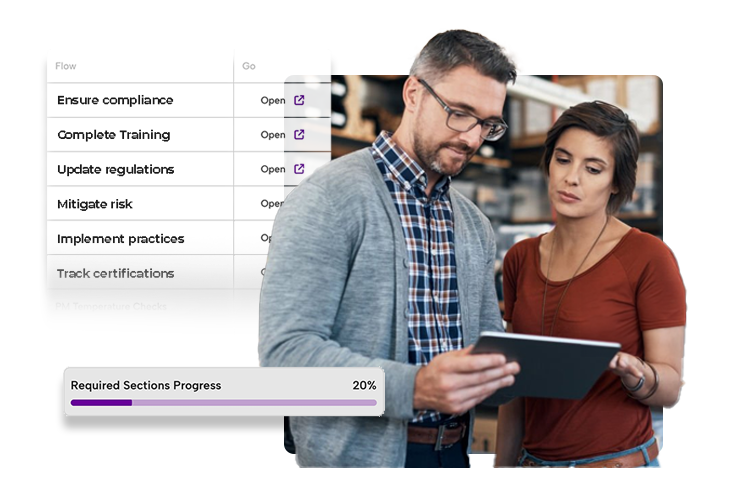

Training and Documentation Management

Proper training is essential when it comes to understanding and implementing proper food safety practices and procedures. To mitigate risk and ensure compliance, mpro5 supports training and documentation management with food safety training software to ensure employees and managers are up to date with the latest food safety requirements and regulations. By delivering training materials, as well as tracking employee certifications and training records, mpro5 helps organizations ensure employees are knowledgeable on food safety compliance at all times.

mpro5 can help you achieve:

COMPLETE FOOD SAFETY SOLUTION

Maintain impeccable hygiene standards and ensure that every aspect of your food safety protocols are adhered to, delivering peace of mind and protection for your customers.

STREAMLINED AUDIT TRACKING

With real-time updates and comprehensive reporting, ensure that every audit is conducted thoroughly and efficiently, enhancing the integrity of your operations.

ENHANCED COMPLIANCE ASSURANCE

Gain the confidence that comes from comprehensive compliance, detailed record-keeping, and proactive management of all regulatory obligations.

0

INSTANCES OF

UNSAFE FOOD

150+

MILLION SAFE

MEALS SERVED

175+

MILLION

JOBS CREATED

We've helped others

overcome challenges you face:

Checkout the latest insights from our industry experts:

3 min read

Ensuring Compliance in the Food Industry: Strategies for Channel Partners and Industry Leaders

Businesses must ensure they are compliant with Natasha’s Law amid continued allergen woes

Start streamlining your processes today!

Click the button below to complete the short form, and we'll be in touch soon!

Food Safety & Quality Software FAQs

-

What is food safety and quality software?

Food safety and quality software is a specialized digital platform designed to manage and maintain the standards of food products. It ensures that all processes, from sourcing to production and distribution, adhere to the strictest safety and quality guidelines.

-

Why do I need food safety and quality software?

-

- Consistency: Guarantees consistent quality across all food products.

- Traceability: Provides detailed tracking of food items throughout the supply chain.

- Compliance: Ensures compliance with food safety regulations like FSMA, HACCP, and ISO standards.

-

-

Can food safety and quality software help with regulatory compliance?

The software is essential for:

- Record Keeping: Maintains detailed logs of quality checks and safety measures.

- Alerts and Reporting: Generates automatic notifications for potential issues and compiles reports for regulatory submissions.

- Process Control: Standardizes processes to meet regulatory requirements consistently.

-

What are the competitive advantages of food safety and quality software?

-

- Brand Reputation: Maintains high standards that enhance brand trust and loyalty.

- Risk Reduction: Proactively identifies and mitigates potential contamination risks.

- Market Responsiveness: Quickly adapts to new regulations and consumer demands for food safety and quality.

-